Application:

Metal Fabrication

Maintenance and Repair

Auto Body,

Light Industrial, Workshop

Processes:

Pulse Process For M.S/AL

Double Pulse Process For M.S/AL

MIG/MAG

Flux-Cored

MMA(Stick)

Input Power:

1PH ~ 230V ±15%/3PH ~ 400V ±15%

Amperage Range: 10-250A

Rated Output at 40℃ (104℉):

250A at 26.5V @60% Duty Cycle

Weight: 32KG

Advanced Features

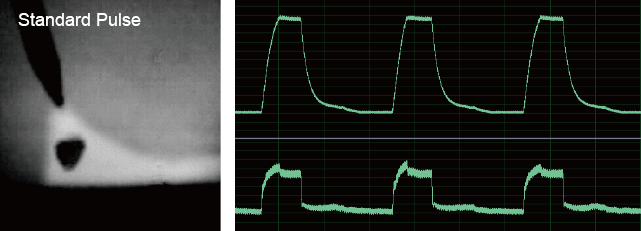

Pulse MIG

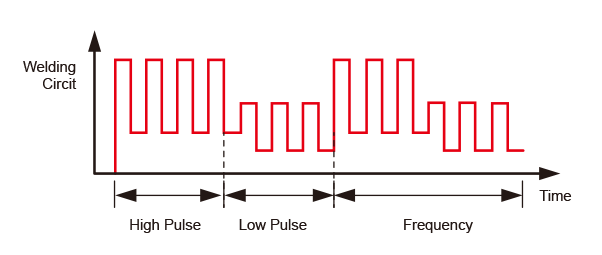

Double Pulse

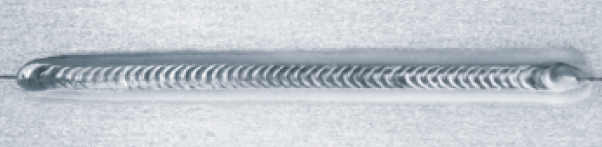

No need to swing, You can easily get a cosmetically pleasing weld seam, with significantly lower and more controller heat input into the workpiece. It results in much lower distortion and less rework for Mild steel and Aluminum sheets.

By Double Pulse process, the heat input of arc is alternating, effectively reducing the heat input of base metal. It reduces the occurrence of welding defects such as crack. Welding quality is comparable to TIG process.

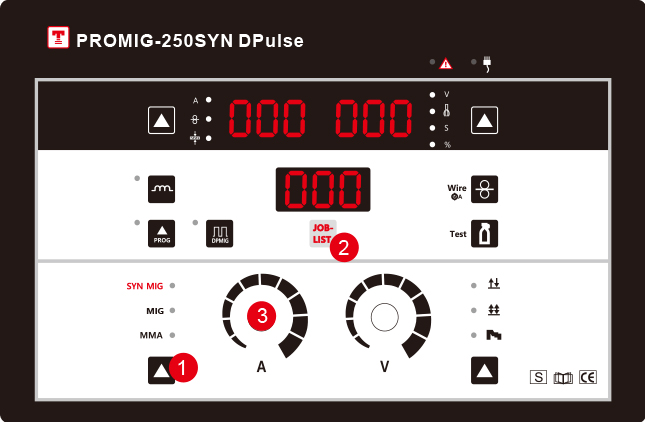

Simple Operation

3 Steps to achieve weld perfection

1. Select operation mode

2. Select Job-list No.

3. Adjust welding current

(always the perfect setting by the synergic function using the material thickness)

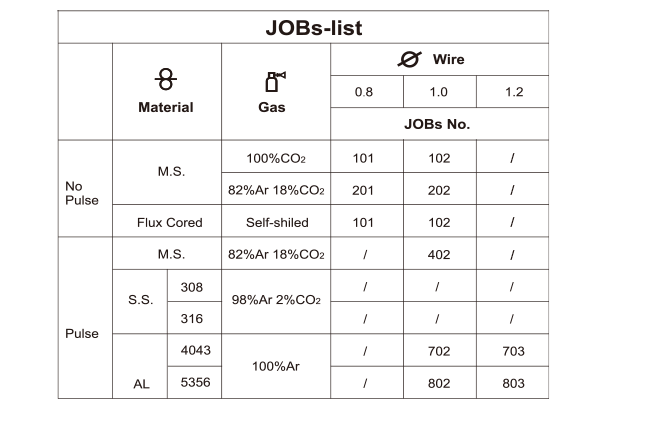

Synergy control with job-list

The Job-lists display is easily and intuitively controlled through its graphical user interface.We assembled the perfect welding curve in every Job-No. for highly efficient multi-process welding of carbon steels and aluminum alloys. Operation is easier than ever before.

Improved Operation Process & Controls

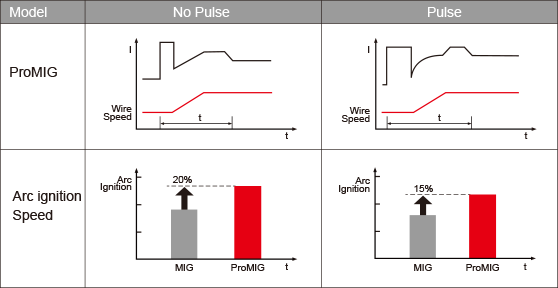

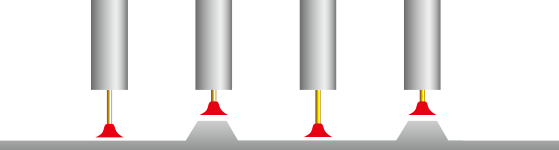

Initial Arc control

We control the arc energy by welding waveform, so the success rate of arc ignition can be improved and quickly establish a molten pool.

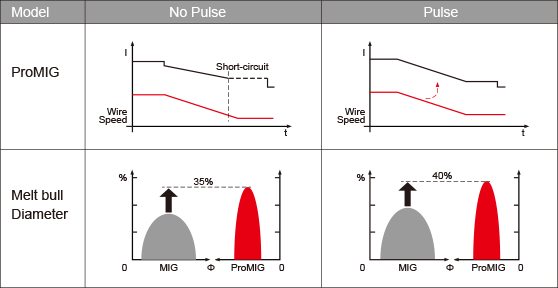

Burn Back control

Adjustable time delay between turning off the arc and the wire feed to prevent wire sticking to the puddle.

Arc Length control

By changing the distance between torch and workpiece. You can now react much more easily to control the arc, such as changing gap dimensions or arc blow, more intuitively and with greater efficiency!

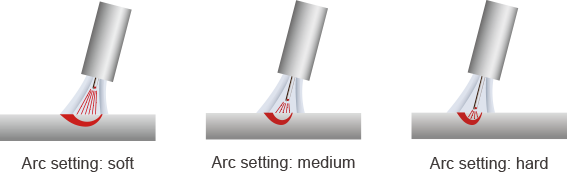

Dynamic control

Dynamic control allows the welder, for the first time, to variably adjust a pulse welding machine to a wide range of jobs and welding positions as well as to his personal preferences. The welder can use a controller to directly access the arc characteristic and change it from soft to hard.

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号